Founded in the yaer 1946 by W-E Wintgens as a small trade company, this business has been taken over by Herbert Genten in 1977 and continually extended since.

Presently, the two brothers Bruno and Stephan Genten are managing the company in second generation.

Annick and Nicolas Genten are now the third generation to join the family business.

All three generations work hand in hand and try to face the challenges of the present and the future together.

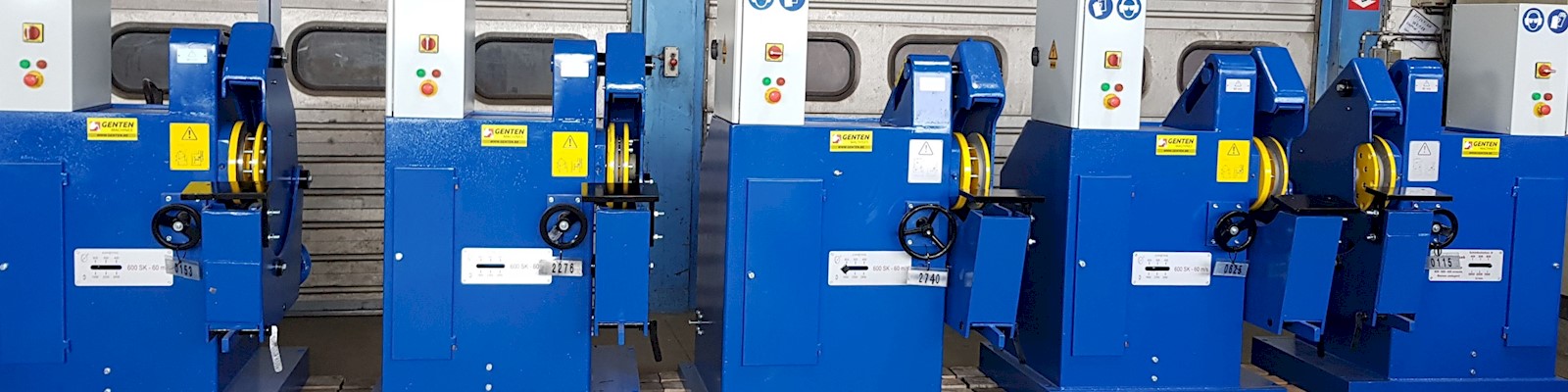

We supply foundries all over the world with used machines and plants, which are carefully checked in our workshop or overhauled according to current safety standards, as required.

Due to our enormous stock in Schoppen (Amel), where all machines find a place on 13 000m² halls and a large outside storage area of 17 000m², we have a wide range of products that makes the heart of a foundryman beat faster. Our constant efforts to provide the best quality, on-time service and a wide range of used machines and spare parts make us a trusted partner for foundries all over the world.

Furthermore, we sell new machinery (ACETARC foundry ladles, LÜBER gas generators) as well as DIAMANT Metalplastic products and BRANTH-KORRUX rust protection paints.

Genten's full service comprises quotations, technical support, delivery, installation and commissioning of a turnkey foundry or individual machines as well as the after-sales service.

18 employees endeavour to satisfy our customers and to ensure a continuous development of our family business. They are always aimed to respond to the request of our times.

By refurbishing older machines, we produce sustainably but with a high demand on quality

We work determinedly and flexible on solutions for our customers. Every challenge strengthens the team spirit.

By refurbishment of used machines, the purchase is not only sustainable, but also cheaper than a new purchase with the same quality and productivity.

We are an honest and respectful partner and particularly value mutual trust

We plan, construct, and modernise machines and plants, which we adapt individually and according to customer requirements.

We work hard every day to satisfy our customers as permanent partners.

With our long experience in the foundry sector, we have the necessary expertise to support you in your projects.

We offer complete and turnkey projects, whereby all work from the planning to the commissioning is carried out by us.

Our workshop has been in existence since 1980. Where previously many repairs were carried out on used machines, today used machines are checked and completely overhauled every day.

Our overhaul can be described in several stages:

-Complete disassembly of the machine into its individual parts.

-Sheet metal working, welding and complete steel construction

-Mechanical, hydraulic and pneumatic modernisation

-Construction of the control cabinet and wiring of the machines

-Programming of the control system

-blasting and painting of the machine

-Assembly of the machine

Team Genten Machines

Our motivated and competent employees are the most important in our company.

Their great competence and considerable know-how are mostly based on a long-standing activity in our house.

They make it possible to deliver customer-specific solutions.

Service-Team Genten Machines

The execution of dismantling, assembly and machine transfers on behalf of customers is also part of our field of activity.

Our assembly and dismantling teams work very efficient, clean and fast.

We have our own modern equipment for this work, such as crane vehicles, various forklift trucks, etc.

We can refer to many years of experience in order to master the most difficult tasks.

There is a solution for every construction site.

There's no such thing as can't!